source:Colorlight

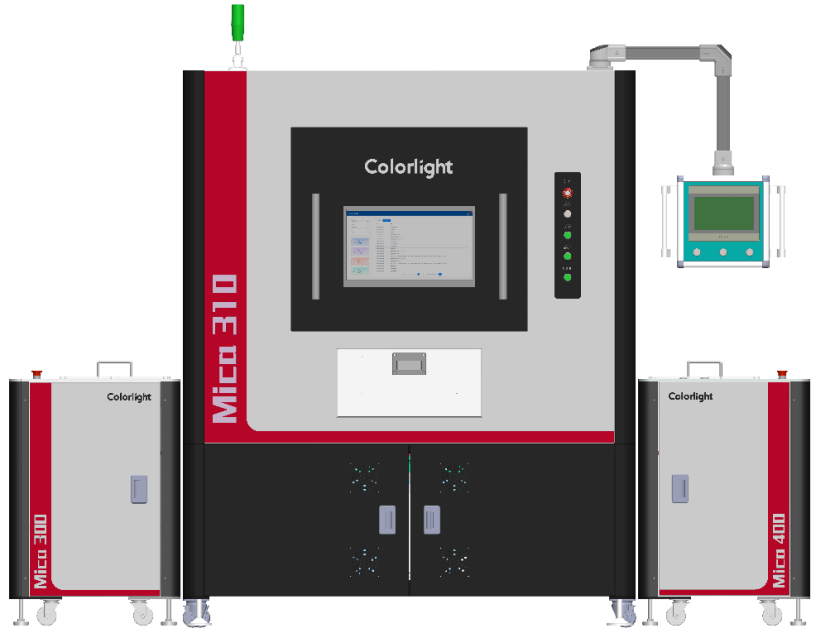

Mini/Micro LED Calibration, also referred to as Mica, is an independently developed automation detection system of production line by Colorlight. This intelligent system can seamlessly detect and sort defective products, and integrates scientific-grade image capture equipment, production line equipment, and data storage&management servers. Furthermore, it includes software platforms for development, debugging, and monitoring, encompassing order management, automated production manufacturing, data storage management, post-sale maintenance modules, and etc. It achieves comprehensive management of the entire industrial product production process. By enhancing production efficiency and detection effectiveness, a comprehensive management of the entire industrial product production process has been achieved, including standardized production management processes, ensured data security, and reduced the difficulty of manipulation, and after-sale costs.

Machine Vision and Industrial Digitization

Mica system integrated AI algorithms into image capture, subtly harmonizing machine vision with industrial digitization. It addresses issues associated with manual visual inspection, such as low accuracy, high error rates, fatigue, or time-consuming efforts, and eliminates common reporting hazards like "missed reports, hidden reports, and incorrect reports." As Mica is applied, production lines enter a highly automated phase, especially evident in lines with high precision requirements and complex processes like character detection and circuit board inspection.

Additionally, Mica features a positioning detection function for barcode character detection and identification, as well as defect detection for medicinal glass bottles. With built-in darkrooms, automatic dust removal with ion wind bars, and modular design for loading, calibration, and unloading stations, the system can adapt to industries with strict environmental requirements, such as healthcare and chip manufacturing.

Artificial Intelligence and Optical Systems

Mica system also applied artificial intelligence into optical imaging systems. Building on its foundational advantages in quantification, grayscale resolution, spatial resolution, and observation speed, Mica utilizes Colorlight's expertise in image and video algorithms. The system equipped with scientific-grade cameras and high-precision optical and temperature-sensitive probes, which can achieve precise and stable brightness data collection and enables accurate analysis and processing for modules of products like COB, SMD, and GOB.

Production Lines and Production Management

Beyond advancements in detection technology, the Mica system achieves intelligent digital management across industrial automation. The system includes one-click startup, automatic feeding, automatic sorting, automatic scanning, and automatic binding and uploading of data. It adapts to MES, ERP, and other production management systems, featuring a data storage management server with cloud storage support for remote access, while unifying the order management, automated production manufacturing, data storage&management, and after-sale maintenance modules, truly realizing an intelligent dark factory.

Hardware Upgrade and IoT Computing

In recent years, machine vision technology in China has gradually shifted towards intelligent vision technology with AI integration. Breakthroughs have been made in the development of intelligent cameras and sensors on hardware, coupled with advancements in optical physics, leading to high-resolution lenses and smaller light sources. These developments enhance the performance of machine vision systems and make them more precise and efficient.

The application of 3D technology provides richer stereoscopic information. Through deep learning and machine learning techniques, machine vision systems can more accurately identify and detect targets, serving a broader range of applications in critical scenarios. With the evolution of IoT and cloud computing technologies, machine vision systems can now achieve real-time data collection, analysis, and remote monitoring. This greatly enhances the intelligence of the production process, enabling the system to make more efficient decisions and problem-solving. Moreover, precise detection and control technology can reduce waste in the production process, improving overall efficiency.

Mica, as a representative of the forefront industrial intelligence era, it not only serves different industries but also continually absorbs and integrates the latest technology, striving for delving deeper into industrial needs and providing robust support for the digital transformation of enterprises.